Technical data:

1. Cycle per minute:15-18bags/min(the speed is related to different SKU)

2.Bag film thickness:0.04mm—1.00mm

3.Packing film material:OPP,complex film

4. Power supply:AC380V,50HZ

5. Pneumatic supply voltage:0.6MPA(buyer needs to provide air supply)

6.Gross power:15KW

7. Packing size:Length:15~32dm,Width:15~30dm, Height:4~21dm (can be customized if needed)

8. Weight: 1800KG

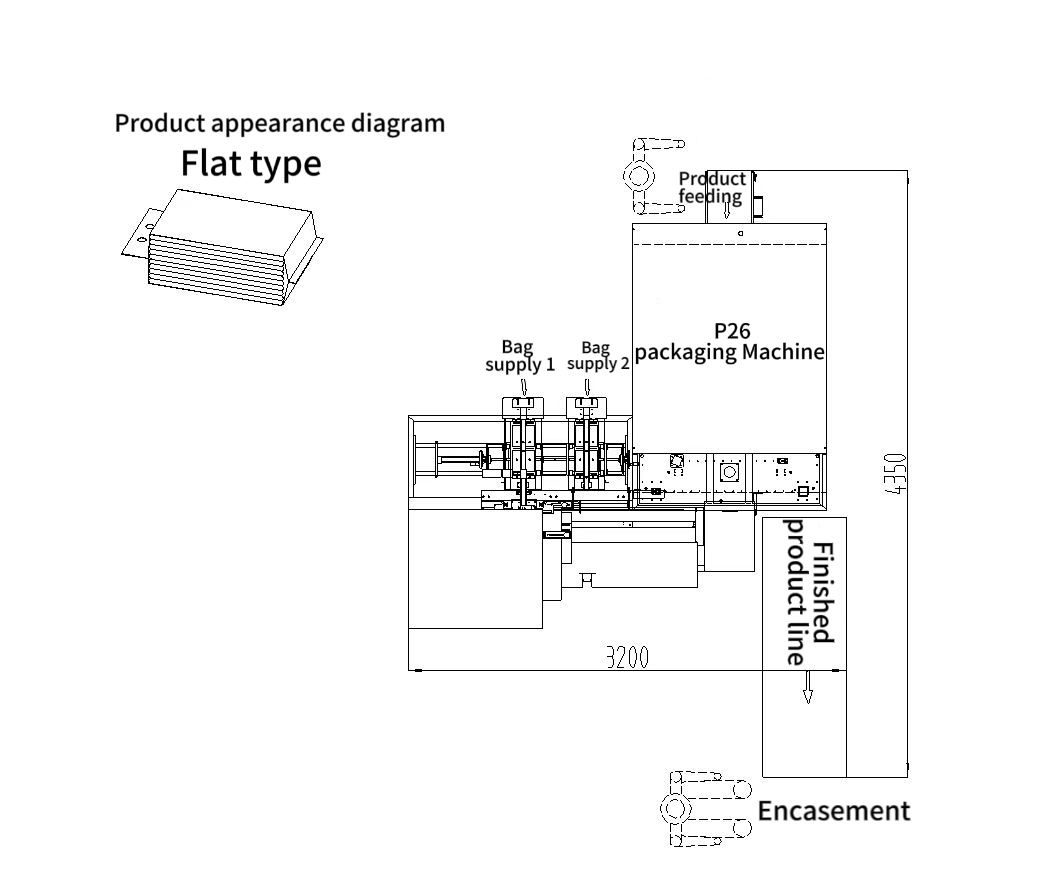

9.Machine space requirement:L43500mm×W3200mm×H2200mm

Advantage:

1.Mainly used for large packaging medical pad,underpad,baby diapers, baby pull-up pants, adult diapers, nursing pads,etc.

2.Fast change-over time: 20-30min for size (two persons)

3.Full-servo control automation system,saving costs,fshorten debugging period,save manpower,lower material,lower labor costs.

4.Bag sealing system: German heat wiring

5.Two bag supplying unit design:one for use; one for back-up

6.Scrap rate:<0.8%

7.Bag Standability:>17 second

8.Bag Seal Integrity :no burn through, no wrinkles ingusseted area, seam stick